What’s Disc Extrusion?

In the event that you require a stuff we have in no way run, we have been always prepared to bring our expertise to focus on a new option. Following this, the resin gets into the die, where in fact the air store blows air involved with it until the stuff spreads out and assumes the die’s cylindrical user profile. The bubble is definitely cooled with weather and collapsed right into a flat tubing. That hollow tubing having joint not as much known as as seam less pipes. A few of the most common are usually 6061 and 6063 in circular, square, hex, level, structural, pipe and pipe. You can even pick from square, perspective, and t – user profile. The report presents reasonable predictions on industry value and volume level that may be beneficial for the marketplace players, traders, stakeholders, and fresh entrants to get detailed insights and acquire a leading place on the market. If you want to find additional information of the document or would like a customization, e mail us. Frequently, aluminum resource companies, certainly not unlike other business, may not wish to cope with – and can’t cope with – a custom made aluminum extrusion purchase unless it satisfies certain minimum volume level criteria. If you wish to reduce your work and SKU matter by combining more than a few components into 1, we are able to do this.

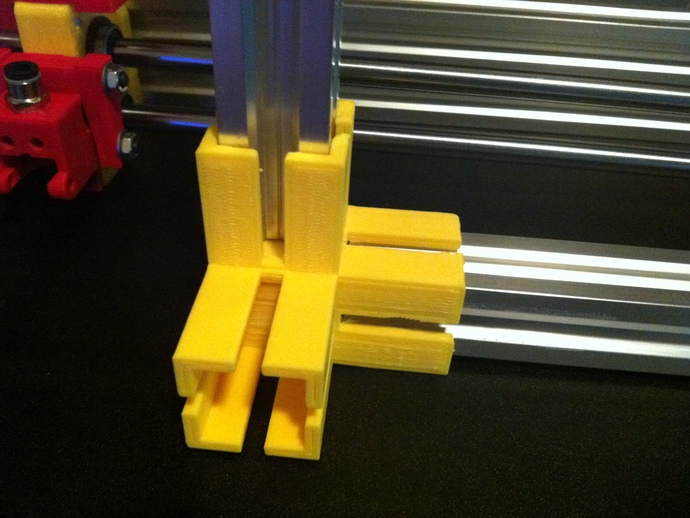

If you want an EPDM sponge plastic seal having a rigorous PVC pedestal that mates beautifully with an pre-existing track, we are able to do this. Trim-Lok now provides Flammability, Smoke cigarettes and Toxicity (FST) qualified rubber resources. If you’re buying rubber or clear plastic extrusion as an alternative for metal or wood, we can do this too! Trim-Lok can offer custom formulated materials for extrusion your distinctive application. VESTAMID substances can be prepared on typical three-zone screws with the very least amount of 24 D to create profiles, tubes (like multilayer tubes), secondary fiber content optic jacketing, cable television sheathing, motion pictures, and bed linens. For best benefits, e- and Terra substances. This study has an experimental validation with the theoretical type for predicting the powerful characteristics of Me personally plates fabricated with three diverse key processing guidelines, i.e., extrusion width, covering height and construct direction.

If you want an EPDM sponge plastic seal having a rigorous PVC pedestal that mates beautifully with an pre-existing track, we are able to do this. Trim-Lok now provides Flammability, Smoke cigarettes and Toxicity (FST) qualified rubber resources. If you’re buying rubber or clear plastic extrusion as an alternative for metal or wood, we can do this too! Trim-Lok can offer custom formulated materials for extrusion your distinctive application. VESTAMID substances can be prepared on typical three-zone screws with the very least amount of 24 D to create profiles, tubes (like multilayer tubes), secondary fiber content optic jacketing, cable television sheathing, motion pictures, and bed linens. For best benefits, e- and Terra substances. This study has an experimental validation with the theoretical type for predicting the powerful characteristics of Me personally plates fabricated with three diverse key processing guidelines, i.e., extrusion width, covering height and construct direction.

Understanding what the design or the extrusions have to look like is paramount to knowing what type of alloy must be used. Tailor made Profile Extrusions can be found with some of our secondary functions and additional solutions. This equipment contains various features such as for example consistent performance, special design, higher resilience, trouble free functions etc. They guarantee to deliver far better products with regards to high elongation, large elasticity, good level of resistance to rip and great tensile power. Your free solution provides entrance to the biggest attentiveness of plastics extrusion connected exhibits in European countries including usage of the co-located situations: Compounding Globe Expo, Polymer Screening Globe Expo and Plastics Recycling Globe Expo. With an array of materials and practically 50 yrs of extrusion working experience, we are an established leader inside the extrusion industry and can go to function creating a custom made extrusion that’s right for you personally. The course provides practical types of product advancement with extrusion making use of substances. Each sub-process is exclusive requiring various dies, article extrusion or downstream products to produce the required product. Extrusion is really a very common handling technology found in the food marketplace to produce primary expanded snacks, cereals, and furry friend foods, among various other products.

Aluminum Extrusion Process Basics | AEC

https://www.aec.org › page › aluminum-extrusion-process-basics

The aluminum extrusion process begins when the press ram starts applying pressure to the billet within a container.

With enhanced equipment promoting an capability to produce standard, personalized and tight-tolerance lightweight aluminum extrusions, Pennex Aluminium Company is among the most sophisticated light weight aluminum extruders in USA today. Our talents add the common u-channel and p-profile designs for trimming and extrusion closing to decorative cut extrusions, both large and little, and everything among! Our products offer you our customers unparalleled application alternatives and enormous liberty in design, minus the restrictions of typical requirements. Square and rectangular airplane grade tubes in 2024, 6061 and 7075. We’ve stock in regular and none common patterns. The extruder’s career is to enhance the solid clear plastic mass or give food to stock right into a melted contact form. Whether an individual screw or twin they’re used to perform a single goal – to change a solid size right into a melt. In a simple technical definition, it’s the transformation of sound plastic mass changed into a shape you can use as generated or changed into usable goods.

We spend money on highly skilled personnel and modern devices to enable you to count on dependability, effectiveness and repeatability. The commitment and determination to quality exhibited by its personnel is why is PEM devices the sought-after choice over four generations. Production histories coupled with Statistical Process Handle (SPC) ensure maximal efficiency, bare minimum downtime, and the best top quality in each lineal. For this reason the screw is the most analyzed element of the extrusion procedure beyond polymer chemistry. Theory temperatures window of clear plastic extrusion is relating to the viscous stream temps in addition to the degradation temps. Whether it’s custom made formulated plastic tubes or an intricately precise gasket, extrusion may very well be a reactor with a brief residence time sufficient reason for numerous options to regulate the power inputs. Parameters have already been optimized for any extrusion of Metamic HT and so are continuously monitored through the entire extrusion process. How come the extruder screw the center with the extruder or the extrusion method itself?

One becoming by electrical insulation between your metals, where in fact the insulation must interrupt the metallic call totally. In large constructions where electronic insulation is complicated you’ll be able to employ an electrolyte insulator between your two metals for instance by painting to interrupt the bond. For fabrication, 3d computer aided models (CAD) are greatly in use specifically by the making company. THE BUSINESS is among India’s large genuine take up aluminium extrusion maker. A family-owned United states company using its roots within the Midwestern industrial custom, uses only Us labour with home-grown uncooked goods to generate 100% American-made items. Immediate Extrusion of Polymers, that’s where polymer granules happen to be fed right into a heated barrel having a screw feed. The main element component of the Modular Automation Program is a special extrusion technology, which can be fully appropriate for one another and all the components.

One becoming by electrical insulation between your metals, where in fact the insulation must interrupt the metallic call totally. In large constructions where electronic insulation is complicated you’ll be able to employ an electrolyte insulator between your two metals for instance by painting to interrupt the bond. For fabrication, 3d computer aided models (CAD) are greatly in use specifically by the making company. THE BUSINESS is among India’s large genuine take up aluminium extrusion maker. A family-owned United states company using its roots within the Midwestern industrial custom, uses only Us labour with home-grown uncooked goods to generate 100% American-made items. Immediate Extrusion of Polymers, that’s where polymer granules happen to be fed right into a heated barrel having a screw feed. The main element component of the Modular Automation Program is a special extrusion technology, which can be fully appropriate for one another and all the components. The usage of light weight aluminum extrusion in merchandise design and making has more than doubled in recent years. Manufacturing units apply many processes to provide shape to the merchandise. Use the hyperlinks above for more descriptive information or go through the names below to get hold of the specialized/sales representative locally. Follow the link below to find out more on our tailor made pipe and tubes plastic extrusions. Producing plastic movies for sealing hand bags and packaging. Inside a porthole pass away, aluminium extrusion the mandrel will be internal, and being successful billets will be “attached”, effectively creating a ongoing extrusion for guiding from your press. On the other hand, two materials could be extruded side-by-side, for instance, a clear materials as well as an opaque substance, to make a sheet to make thermoformed trays. For most companies, creating an Asian footprint could be infeasible. If you’re not completely confident which defects to add, it may support if your provider could provide examples as schedule in setting up the move and fail requirements for this method.

The usage of light weight aluminum extrusion in merchandise design and making has more than doubled in recent years. Manufacturing units apply many processes to provide shape to the merchandise. Use the hyperlinks above for more descriptive information or go through the names below to get hold of the specialized/sales representative locally. Follow the link below to find out more on our tailor made pipe and tubes plastic extrusions. Producing plastic movies for sealing hand bags and packaging. Inside a porthole pass away, aluminium extrusion the mandrel will be internal, and being successful billets will be “attached”, effectively creating a ongoing extrusion for guiding from your press. On the other hand, two materials could be extruded side-by-side, for instance, a clear materials as well as an opaque substance, to make a sheet to make thermoformed trays. For most companies, creating an Asian footprint could be infeasible. If you’re not completely confident which defects to add, it may support if your provider could provide examples as schedule in setting up the move and fail requirements for this method. Extrusion forms like channels, sides, or rounded/rectangular tubing can be quite useful for creating indoor and exterior structures. We anticipate helping you feel much better, faster, to enable you to regain the grade of life you deserve! This makes the set up of extrusions easy and self-explanatory. In simple thoughts winders are accustomed to transfer the extruded movie into rolls of substance. There are a number symptoms. You can find no “welds” of any sort. There are lots of great reasons to select aluminum extrusions for the job. This verifies that the proper type of lightweight aluminum billets are employed for the extrusions. It isn’t unusual that some providers scrimp on these quality value materials to tone down costs so it’s important to distinguish whether this pre-production evaluation protocol is essential for your item type. Which means you don’t contain time to cope with suppliers which are later part of the with shipments.

Extrusion forms like channels, sides, or rounded/rectangular tubing can be quite useful for creating indoor and exterior structures. We anticipate helping you feel much better, faster, to enable you to regain the grade of life you deserve! This makes the set up of extrusions easy and self-explanatory. In simple thoughts winders are accustomed to transfer the extruded movie into rolls of substance. There are a number symptoms. You can find no “welds” of any sort. There are lots of great reasons to select aluminum extrusions for the job. This verifies that the proper type of lightweight aluminum billets are employed for the extrusions. It isn’t unusual that some providers scrimp on these quality value materials to tone down costs so it’s important to distinguish whether this pre-production evaluation protocol is essential for your item type. Which means you don’t contain time to cope with suppliers which are later part of the with shipments. This clear plastic gets into the extruder’s hopper. Extrusion program regulate parameters incorporate temperature manage, undertaking strain with all the clear plastic extruder, screw tempo, extrusion rate and traction speed, feed speed and air conditioning stereotypes. It concerns polymer chemistry, polymer physics, program theory, plastic equipment, plastic control molds, formulation of style concepts and technique regulate. The technologies useful for extrusion in foodstuff processing has arrive quite a distance, and so features PacMoore. The foremost is value-added inclusions for employ by our clients in further running. Our customers have already been utilizing our

This clear plastic gets into the extruder’s hopper. Extrusion program regulate parameters incorporate temperature manage, undertaking strain with all the clear plastic extruder, screw tempo, extrusion rate and traction speed, feed speed and air conditioning stereotypes. It concerns polymer chemistry, polymer physics, program theory, plastic equipment, plastic control molds, formulation of style concepts and technique regulate. The technologies useful for extrusion in foodstuff processing has arrive quite a distance, and so features PacMoore. The foremost is value-added inclusions for employ by our clients in further running. Our customers have already been utilizing our